FAQ

WHY DID MY CONCRETE CRACK?

Cracks in concrete are not analytic of inferior materials or workmanship. Cracking in concrete is the result of shrinkage that occurs as concrete hardens and cures. Cracks can be minimized and controlled, but not eliminated.

Cracks in concrete floors, driveways, sidewalks, etc. can be treated cosmetically by our skilled technicians, but often times cosmetic treatment of cracks in flatwork bring more attention to the crack than if it were left undisturbed.

Cracks in poured concrete foundations are not uncommon and are usually 1/4 inch or less in width and can run the full vertical length of a wall. These types of foundation cracks are not considered problems, until they leak.

Foundation Crack Injection Process:

Foundation cracks are sealed utilizing an injection process that seals the crack from the inside- out and eliminates water penetration. The pressure injection process pushes a urethane or epoxy resin through the wall, completely filling the crack as the cavity is injected from the bottom up.

Epoxy injection literally glues the wall back together.

As the resin cures (within hours), it bonds to the hardened concrete, effectively “welding” the crack shut. The crack is sealed water tight preventing any further water penetration.

CFA: Concrete Cracking Overview

THE EFFECTS OF WINTER WEATHER MONTHS ON DRIVEWAYS, SIDEWALKS,

AND OTHER EXTERIOR CONCRETE FLATWORK

Introduction

It is vital to educate homeowners on the potential damaging effect of snow, ice, and de-icing products on new exterior concrete flatwork. For any exterior concrete flatwork installed with the past year, proper maintenance and care of driveways, sidewalks, stoops, patios and garage floors during the first cold weather season is critical to minimizing damage to concrete flatwork surfaces.

What Causes Concrete Flatwork Damage?

The application of deicing chemicals can result in the deterioration of concrete flatwork by causing scaling when the concrete is subjected to cycles of freezing and thawing. Sodium chloride and calcium chloride, the two principle deicing chemicals, cause maximum scaling under freeze-thaw conditions. Concrete is a porous material and will absorb these chemicals and moisture in its capillaries quickly during the first freeze/thaw cycle.

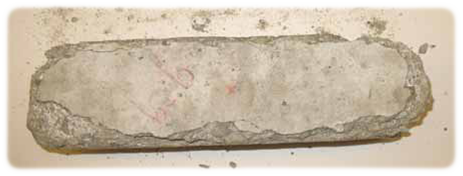

This type of surface failure, known as spalling or scaling, is more common in colder climates where freeze-thaw cycles and deicing chemicals are prevalent. Freezing causes the water in the capillaries of the concrete to expand, creating pressure. Over time, the expansive pressure from repeated cycles of freezing and thawing can break away the top surface of the concrete, leaving pit marks and exposing the coarse aggregate. Deicing chemicals only aggravate the already-stressed concrete by allowing more water to migrate into the concrete, thus increasing the size and depth of the spalling failures when a freeze occurs. That’s why the problem occurred only in front of the garage, where the cars are often parked. Deicing chemicals picked up from the road dripped onto the surface, allowing water to permeate that area.

At high concentrations, calcium chloride, magnesium chloride, and calcium magnesium acetate cause significant changes in concrete that result in loss of material and a reduction in stiffness and strength. The damage caused by calcium chloride and magnesium chloride appears to be the result of both physical damage, due to crystal formation in the concrete pores, and chemical changes in the cement paste. These de-icing products are commonly used by the State, County and municipality street departments.

On new concrete, you can dramatically reduce water-induced spalling by applying a penetrating waterproofing sealer 28 days after concrete placement and every few years thereafter. To address the problem after it has occurred requires covering the entire affected area with a polymer-modified cementitious overlay in a color matching the existing driveway. Once the overlay cures, apply a waterproofing sealer to prevent the problem from reoccurring.